On a Saturday…

On a Saturday…

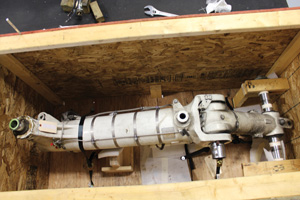

A Flight Data Recorder that was on its way to an operator in Moanda, Gabon, Africa, from Phoenix, Arizona, U.S., by way of Boulazac, France, was stopped at the border of Gabon, tied up in the red tape of African Customs. The paperwork was denied by the Customs agency and the unit was not allowed to enter the country.

…do you wait until Monday to respond?

The business of business aviation does not sleep, especially when you consider the size of the industry and that all of the major players conduct business across several time zones, international borders and oceans.

It comes as no surprise to anyone at Duncan Aviation when a customer contacts us over a weekend with an urgent need; in the business of business aviation, there are no weekends.

Case in point: Jewell Chambers, a senior international parts sales rep for Duncan Aviation’s Parts and Rotables Sales, left work as normal on a Friday afternoon, looking forward to the weekend and her grandson’s fifth birthday.

She always enjoys her time away from work, but her customers are never far from her mind. Duncan Aviation Parts and Rotables Sales has 24/7/365 coverage, even on evenings and weekends. There is always someone available to answer the phones.

But when you’ve been doing this as long as Jewell has, you build relationships and long-time customers contact you directly. It has become part of her routine to check her email every Saturday and Sunday morning to make sure her customers in Europe don’t have pressing needs. On this particular Saturday, she received the urgent email above.

Jewell and her grandson, Riley, celebrating his fifth birthday.

Jewell and her grandson, Riley, celebrating his fifth birthday.Jewel doesn’t mind helping her customers on the weekends, because if it is critical to them, then it is critical to her. She responded back with, “I’m on my way to the office to get you what you need.”

Within an hour, the proper invoice was on its way to Gabon by way of her customer in France and the unit was allowed into the country.

The weekend is her time away from work, but her commitment to doing the right thing by her customers saved them more than 36 hours of waiting. In her line of work, that is too long.

Besides, she made it back home in plenty of time for the birthday party.

Read more from the Fall 2015 Duncan Debrief Magazine

The Duncan Debrief free publication is available for aviation enthusiasts around the world through mail and online. To receive the magazine, subscribe here. Have an iPad? Access the magazine through the Duncan Debrief app. Search for Duncan Debrief in Apple’s App Store and download it. Once downloaded, you can receive push notifications each time a new Duncan Debrief magazine is published.

We are one big extended family. When I walk through the hangars I’m not just talking with employees and customers, but with friends.

We are one big extended family. When I walk through the hangars I’m not just talking with employees and customers, but with friends.  Doug Roth, Duncan Aviation Aircraft Sales

Doug Roth, Duncan Aviation Aircraft Sales In The Beginning...

In The Beginning... Today, Airesearch is now Honeywell and Duncan Aviation Engine Services has grown to include 73 licensed factory-trained turbine engine technicians working two shifts to provide line maintenance, MPIs, AOG road services and technical expertise, in support of Honeywell, Pratt & Whitney, Rolls Royce and Williams International aircraft turbine engines.

Today, Airesearch is now Honeywell and Duncan Aviation Engine Services has grown to include 73 licensed factory-trained turbine engine technicians working two shifts to provide line maintenance, MPIs, AOG road services and technical expertise, in support of Honeywell, Pratt & Whitney, Rolls Royce and Williams International aircraft turbine engines. We all know the drill. As soon as the ball drops we make promises to ourselves to improve life in the coming year. The most common resolutions are to improve fitness, stop vices or change a behavior.

We all know the drill. As soon as the ball drops we make promises to ourselves to improve life in the coming year. The most common resolutions are to improve fitness, stop vices or change a behavior. Original R&D Team circa 1984

Original R&D Team circa 1984

2016 is a special year. It is Duncan Aviation’s 60th year of helping business aircraft operators be safe, efficient and productive. For six decades, customers have asked us for solutions and services. We are celebrating our 60 years by telling the stories about the people of Duncan Aviation who listened and took action.

2016 is a special year. It is Duncan Aviation’s 60th year of helping business aircraft operators be safe, efficient and productive. For six decades, customers have asked us for solutions and services. We are celebrating our 60 years by telling the stories about the people of Duncan Aviation who listened and took action. We tore down our website and built a new one. One that we are sure you’re going to love!

We tore down our website and built a new one. One that we are sure you’re going to love!