Contributed by Jerry Cable, Accessory Tech Rep

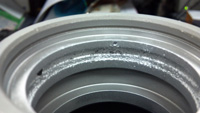

During recent inspections, Duncan Aviation accessory technicians have found corrosion on the pistons in the Main Actuator. This area becomes susceptible to corrosion when there is a lack of lubrication on the piston rod felt wiper. Without lubrication the felt absorbs water and begins to corrode the piston and aluminum housing. If corrosion develops, the piston must be sent out to be re-chromed at a minimum of a six-week downtime or replaced with a new unit. There is no repair for the aluminum housing, it must be replaced.

When the aircraft sits idle, the actuator is fully extended. This is when the shaft should be lubricated. Lubricating the piston rod felt wiper is a Chapter Five item. Refer to the Learjet Maintenance Manual for the proper procedures and frequency.

Scheduled to open in August of 2013, Duncan Aviation's Accessory Shop at its Lincoln, Neb., location, will gain approximately 6,300 square feet with the refurbishment and expanded footprint of its service area. Read more about how Duncan Aviation is investing today to be prepared for tomorrow in the Spring 2013 issue of the Duncan Debrief.

Jerry Cable is an Accessories Tech Rep located at Duncan Aviation’s Lincoln, Nebr., facility. He is a landing gear and accessory components and systems specialist. His aviation career began in 1991.