Contributed by Dale Hawkins, airframe service sales rep.

Business aircraft budgets are tight. Firm Fixed Pricing gives more control over maintenance expenses.

When it comes to business aircraft maintenance costs, most operators are able to effectively budget what they want to spend on interior, paint, and avionics. But when it comes to airframe maintenance, there are many unknowns. Even a well-educated guess can still result in the Director of Maintenance (DOM) having to explain why the aircraft maintenance costs came in higher than expected. Firm Fixed Pricing offers business aviation customers a guaranteed labor price for scheduled inspection packages, giving more control over maintenance expenses.

How does Firm-Fix Pricing work?

An MRO offering Firm Fixed Pricing agrees to perform scheduled inspections and all discrepancies noted as a result of these inspections at a predetermined fixed price. The price includes the inspection labor (often called flat rate), miscellaneous parts needed for the inspection, labor for discrepancies noted as a result of the inspection (unknowns) and all consumables. Due to continuous price fluctuations, major parts or outside vendor services are not included in Firm Fixed Pricing.

With all the unknowns, how is an MRO able to offer Firm Fixed Pricing?

Knowledge and experience is the only way a qualified MRO is able to offer Firm Fixed Pricing. Through years of performing the same airframe inspections over and over, innovations are discovered, efficiencies are gained and valuable historical data is collected; reducing the risk of a guaranteed labor rate.

Why aren’t more MROs offering Firm Fixed Pricing?

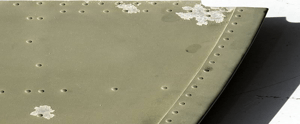

Simply put, the potential risk of losing profit margins is just too high. The majority of the reluctance stems from the unknown possibility of discovering major corrosion damage during an airframe inspection. A discovery of this type is not uncommon and can escalate the cost and extend the downtime of any airframe inspection.

Minor airframe corrosion is covered under the Firm Fixed Pricing program and corrosion that requires Engineering Services from the OEM are offered at an exceptionally discounted rate.

Firm Fixed Pricing for Falcon Airframe

Duncan Aviation has been offering Firm Fixed Pricing on Falcon airframes for six years. Since then many Duncan Aviation customers have taken advantage of the guaranteed labor rate. Here’s what a few have had to say.

Ken Peartree, Hewlett Packard DOM — “No other company was willing to use such a creative approach. It was great for us!"

Joe Sasser, DOM — "I challenged Duncan Aviation to create this program as I believe the industry is moving that direction. We performed two separate C inspections on our Falcon 50 and 900EX. We were very pleased with the team's performance and our accounting department loved knowing where we stood before performing the work."

Chuck Baker, Greenleaf DOM— "I have maintained this aircraft for many years, but never been to this level of an inspection. I really don't know what will be found. I do suspect there will be some S-duct cracking and possibly some tank corrosion. Given that, we believe Duncan's Firm Fixed is the way to go!”

Bottom line for us is simple. Duncan Aviation has a tremendous amount of history and expertise with all Dassault airframes that we are willing to take the risk for our customers.

Our relationships with our customers are very important to us. We continually look for ways to enhance and improve their Duncan Aviation experience and are challenging our other teams to pursue offers of Firm Fixed Pricing for other airframe types. Stay tuned.

Let's Talk Firm Fixed Pricing at EBACE

Dale is attending European Business Aviation Convention and Exhibition (EBACE) in Geneva, Switzerland, May 14 – 16. If you have any questions or want to talk about Firm Fixed Pricing for you next Falcon inspection, schedule an appointment with Dale or stop by Duncan Aviation’s stand #456.

Dale Hawkins is an Airframe Service Sales Rep at Duncan Aviation’sBattle Creek,MI, facility. He specializes in the Falcon and Hawker airframes. His aviation career began in 1981.