Panorama of southern Utah Lake.

Don’t know what to do while your aircraft is at Duncan Aviation for a multi-shop inspection for several weeks? Here is a detailed travelogue from Mariusz Wieczorek, a Duncan Aviation customer from Poland who spent several weeks downtime at Duncan Aviation for an 8C inspection.

Read about his firsthand account on what to do, where to go and who to talk to when on the ground at Duncan Aviation in Provo, Utah.

Mariusz Wieczorek's Excellent Adventures

Mariusz (R) reaches the summit of Mt. Nebo with Duncan Aviation Airframe Technician Daniel Goheen (L).

Sunset in Arches National Park.

Bonneville Salt Flats.

Viewing from the air the same mountains I climbed the day before.

Enjoying the challenge of mountain biking.

Camping in Grand Canyon.

Taking a plunge into Lake Powell.

Maybe it’s because I come from a country where summer time usually looks like Scotland’s fall. Maybe it’s because I’ve never left my continent before, but one this is for sure–after spending time in Provo, I can definitely say or rather shout: “I love Utah!”

I knew nothing about Provo or Utah before it was decided we were going to have Duncan Aviation perform an 8C check on our business aircraft at their facility located there. Though I’d heard about places like Salt Flats, Salt Lake, Bryce Canyon and Zion’s National Park, I was eager to do some exploring on my own. The entire state offers a vast and beautiful, sometimes dangerous landscapes where you can hide for days having only bear, wolves and mountain cats as company. You may even find a deer blocking your car in the parking lot.

After you’ve landed at Duncan Aviation in Provo, Utah, (PVU) and conducted business setting up maintenance and repair schedules, leave your aircraft in their capable hands. Let them do their job. They know what they’re doing.

Hiking, Biking, Flying and More!

There is no need to travel far to see the beauty of the state. If you like hiking, Mt. Timpanogos (elev. 11,752 ft.) is the highest peak within a few miles of Provo to scramble on. Go north through beautiful Provo Canyon on your way to the Aspen Grove Trailhead. Make sure to stop at the Sundance Resort along the Alpine Loop Scenic Byway for a decent meal, because you’re going to need it! During this 8-10 hour scenic hike, you will cross beautiful waterfalls, stand at the edge of Emerald Lake with its glacier and see curious mountain goats or possibly a moose or two before you reach the summit. The 360 degree view is astonishing and will make all the effort worth it.

Mt. Nebo (elev. 11,928 ft.), is another nearby peak 20 miles to the south. The Mt. Nebo Loop is a scenic serpentine on your way to the trail head. This hike is not for the faint of heart. Prepare yourself for a real cardio workout, especially the last mile when the trees stop and birds find no reason to fly there. After you summit, return down the same trail or if you feel up for more physical challenges, continue on through the middle and south Nebo peaks for your descent.

For the most extreme climbing experience, visit Little Cottonwood Canyon north from Provo. You’ll find nice boulders and unique climbing roads cut in the granite walls of the canyon.

Talk to Jason Kinnan, Duncan Aviation’s Parts Specialist in Provo. He is a local Search and Rescue member and knows everything about mountains and climbing.

If you are a biker rather than hiker, there are plenty of roads that lead to some special places. Most of the mountain roads are easily accessible and paved with race cyclists riding all over the place. If you prefer endurance cycling, visit Park City, Utah. Canyon Resort and Sundance Resort are nearby with various trails from easy to hardcore. Rent a downhill bike and have a blast. Remember to wear a helmet and crash pads!

Talk to Glenn Lewman or Shawn Mortensen, two of Duncan Aviation’s airframe mechanics in Provo. They will take you to unique trails in the wilderness far away from bike parks.

Need to get back in the air? Rent a glider, airplane or instructor at Heber City Airport, then fly the very same mountains you just hiked or biked. This is the easiest way to summit. You will experience thermal and ridge lift and possibly even wave activity when in the air. It’s all there.

Just three short miles from Duncan Aviation in Provo, head for Utah Lake State Park. There you can rent a motorboat, ski jet, catamaran, and sailboat. Float down the Provo River in a canoe, take a kite surfing lesson or just lounge on the warm sand and relax.

Are you a golfer? Good. Nearly half of the Duncan Aviation team in Provo is too. They know the best courses.

If you’re visiting in winter time, the skiing and snowboarding couldn’t be any better. Utah Mountains hold the best snows in the world. Jeff Schipper, Duncan Aviation Project Manager knows the best ski areas and equipment.

If you’re a gearhead visiting in August be sure to visit the Bonneville Salt Flats Race Track to see the Speed Week event. This is the place to be for automobile fans. You’ll see speed record machines from motorcycles, cars, hot rods, trucks and many more; speeding around at speeds up to 400 mph. Ward Cranor, Duncan's Lead Structures Mechanic in Provo, is a motor head and will surely take you on a tour.

Night Life and Long Weekends

After all the adventure you can take, find a pub to cool yourself down with various products of local breweries. As a matter of fact, Utah is one of leaders in producing beer in the country and a serious exporter as well. For more night live and social, cultural activities you don’t have to go far; everything is available 40 miles north in Salt Lake City. Or just visit Las Vegas, only about five and a half hours to the south. While there, the Hoover Dam is too close not to see and the south ridge of the Grand Canyon is within grasp.

On a long weekend, head south through Vermillion Cliffs to Zion National Park, climb Angels Landing trail or go for the famous Narrows. Visit Page City and take a refreshing bath at one of Lake Powel’s wild beaches. The water is both super-clear and warm. Then next time, head north and visit Yogi Bear at Yellowstone National Park—it’s only a six hour drive. Good advice: don’t overnight in your car inside the park. You’ll have a chat with the Ranger by the light of the moon.

If you are looking for a maintenance facility that knows how to take care of your aircraft, choose Duncan Aviation. If you want the time to go faster with some off road adventure, Provo, Utah, fits the bill. In addition to incredible service, you’ll have a lot of fun and many tale-worthy experiences you won’t soon forget.

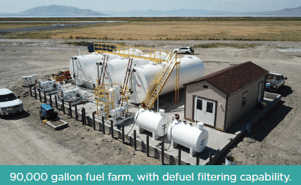

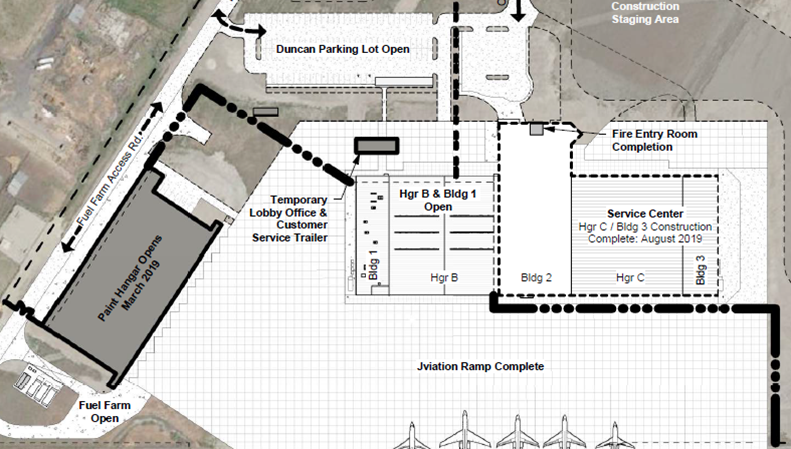

and the entire hangar floor is now in. The Paint Hangar is on track to open in March 2019, and the structural steel is up and being closed in for Hangar C and Building 3 (opening June 2019). The structural steel is also being erected for Building 2 (opening in the first quarter of 2020).

and the entire hangar floor is now in. The Paint Hangar is on track to open in March 2019, and the structural steel is up and being closed in for Hangar C and Building 3 (opening June 2019). The structural steel is also being erected for Building 2 (opening in the first quarter of 2020).

The 14" thick ramp took 35,000 yards of concrete, and 6.5 million pounds of steel.

The 14" thick ramp took 35,000 yards of concrete, and 6.5 million pounds of steel.

Chad Doehring, recently named Vice President of Operations for Duncan Aviation’s Provo, Utah, location, has always loved the mountains. Born and raised in Arvada, Colorado, he spent much of his childhood enjoying hiking, skiing, and camping. After he graduated high school, he won a full-ride scholarship to Colorado AeroTech, where he earned his Airframe & Powerplant license.

Chad Doehring, recently named Vice President of Operations for Duncan Aviation’s Provo, Utah, location, has always loved the mountains. Born and raised in Arvada, Colorado, he spent much of his childhood enjoying hiking, skiing, and camping. After he graduated high school, he won a full-ride scholarship to Colorado AeroTech, where he earned his Airframe & Powerplant license. Chad and his wife, Stacey, have relocated to the Provo area. They are excited about the move, especially because of the recreational and community activities the area has to offer. They are also pleased with the friendly people and the way the community has welcomed them with open arms.

Chad and his wife, Stacey, have relocated to the Provo area. They are excited about the move, especially because of the recreational and community activities the area has to offer. They are also pleased with the friendly people and the way the community has welcomed them with open arms. Extending the full-service Duncan Aviation brand west is exciting for several reasons. This is the company’s first greenfield (completely from scratch) full-service construction effort in our 60-year history. We will be closer to longtime customers from all over the western United States. When the campus is up and running, we will have the world’s most innovative and environmentally friendly paint facility for business jet aircraft. All liquid discharge from the process will be evaporated, with minimal remaining solid waste hauled to licensed handlers. All vapor and airborne discharge from the process will be incinerated, using the very latest technology currently available. Our total discharge will be reduced by 98% from the conventional paint process widely used in the industry today. We have focused companywide on green initiatives for many years, and with the new technologies this construction allows us to put in place, this facility represents a quantum leap forward toward our core value of respecting our environment.

Extending the full-service Duncan Aviation brand west is exciting for several reasons. This is the company’s first greenfield (completely from scratch) full-service construction effort in our 60-year history. We will be closer to longtime customers from all over the western United States. When the campus is up and running, we will have the world’s most innovative and environmentally friendly paint facility for business jet aircraft. All liquid discharge from the process will be evaporated, with minimal remaining solid waste hauled to licensed handlers. All vapor and airborne discharge from the process will be incinerated, using the very latest technology currently available. Our total discharge will be reduced by 98% from the conventional paint process widely used in the industry today. We have focused companywide on green initiatives for many years, and with the new technologies this construction allows us to put in place, this facility represents a quantum leap forward toward our core value of respecting our environment.