Contributed by Curt Campbell, Avionics Tech Rep

Long chains of communication are notorious for 'losing' pertinent information about a squawk.

Remember the “telephone” game when you were a kid? The game where a specific sentence or phrase was whispered to the first person in line and they in turn whispered it to the next and the next, until it got to the last person? Most of the time what the last person heard is nowhere near the original phrase.

Although we may be grown up, we still have similar issues with long chains of communication. In my experience as an Avionics Tech Rep, unless I am talking to the person who witnessed the squawk, I go under the assumption that there is always more to the story than what I am told. Or in some cases, a completely different story altogether.

During a squawk event, the first opportunity for ‘lost’ salient information is with the flight crew. They are tasked with the verbalization of the squawk, and in an effort to be concise, may inadvertently leave out valuable clues that will help pinpoint the cause of the event. They may also be unaware of additional checks or other observations that can aid in troubleshooting. Of course every time the crew’s information is passed on to the Director of Maintenance (DOM), MRO or avionics tech rep, the verbiage is subtlety changed based on the perceptions of each individual, resulting in what in some cases is a completely different squawk than what was originally witnessed. This results in misdiagnosis, expensive parts needlessly changed and lengthy intervals to finally diagnose and clear the discrepancy.

How can you avoid this wasted time and extra expense? Here are some simple tips that can save you in the long-run.

Eliminate the Middleman

llow the person or team charged with resolution of the issue direct access to the crew member who witnessed the issue. Don’t assume you know what the crew saw. Their perceptions may be different than yours

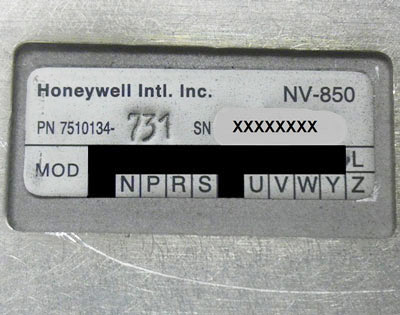

Use That Smartphone as a Troubleshooting Aid

If the issue is visual, take a video of the failure. This is particularly helpful for flight control system problems, which can be difficult to describe accurately. In the case of the flight control system, try to capture the primary flight instruments as well as the yoke movements in the video.

Educate Your Crew

Make sure the crew understands common troubleshooting steps for the specific systems installed in your aircraft. For instance, I often find the crew will observe a flight control system issue at cruise with altitude hold and GPS modes selected, but will not try other modes such as HDG and Pitch hold. Testing these modes at the time the squawk occurs would significantly reduce the required troubleshooting and/or unnecessary parts procurement.

Intermittent & Ongoing Squawks

Send the crew off with a checklist of things to accomplish when the issue occurs. Conditions such as altitude, airspeed, temperature, weather conditions, can all play a roll in determination of the issue.

Call Your MRO Inflight

I’ve participated in ‘live troubleshooting’ calls many times and it works. They can ask questions in real-time, often resulting in quicker diagnosis and faster repair.

Duncan Aviation has twenty Technical Representatives, available 24 hours a day, seven days a week, to troubleshoot and answer questions about every aircraft, engine and avionics system in a business aircraft. They are proactive in their education, taking the necessary steps to stay current on the latest technologies. They spend hours researching the latest Airworthiness Directives (AD), Service Bulletins (SB) and Service Letters (SL) released by the Original Equipment Manufacturers (OEMs) and impart that knowledge to technicians and customers.

Curt Campbell is a Duncan Aviation Avionics Tech Rep. located in Lincoln, NE, specializing in troubleshooting squawks and offering tech support for business aircraft avionics. Curt's aviation career began in 1975.