Five Stitches down…Six stitches across…five stitches up…six stitches across. Repeat…seven times for each row; 25 rows…80 hexagons; 160 hexagons per seat; five seats…800 hexagons, all stitched by hand.

Guided by hand through an industrial Pfaff sewing machine, Niki McClish, upholstery crew leader at Duncan Aviation's Battle Creek, Michigan, facility, diligently repeats this pattern over and over. This work could be done by a machine, but working with your hands brings out the best quality product in the end.

There are always great expectations when designing an interior of a business aircraft. Not wanting to deliver the same look typically seen, Duncan Aviation’s Design team researched high-performance automotive seats in different shapes and sizes. After several trials and experiments, the designers and upholsterers created a napkin sample with a high-contrast hexagon pattern stitched in bold red on light-colored Townsend Leather in a shade called Venetian Lace. At the same time, they added ½-inch quilt foam, giving the design a three-dimensional effect. This sample and model photos showing the seats and divan trimmed in a red Garrett leather piping were shown to the owner.

He loved it.

The first step of any aircraft interior seating project is to make the design look great on paper. The next is a testament to the skill of a talented team of upholstery specialists when they bring that seat design to life.

Many options were considered about how to complete this labor-intensive project, including seeking an outside vendor to machine-stitch the pattern. In the end, quality control and time constraints kept the job in-house.

“It was an easy decision really,” says Multimedia Designer Ken Reita. “We knew by doing the work here at Duncan Aviation, we maintained strict control of the quality and could work easily within the time constraints of the project. But honestly, it was the level of workmanship and the skill of the Duncan Aviation upholstery team that sealed the deal.”

Before the first piece of leather was cut, Niki McClish, upholstery crew leader, and her team had to overcome the constraints of the dynamic certification. The certified 16G seats required critical load areas (seat cushion and back) to have a specific type of foam and density. Ken plotted out the seat design using vendor data and Niki’s input. The rigid, geometric shape allowed for a more computer-aided design, helping Ken to create a very realistic model with correct pattern placement when scaled to actual size.

Man Vs. Machine

The hexagon pattern is a pretty straightforward design, but the strict geometric shape required patience and a critical eye to keep the entire seat pattern symmetrical from side to side and top to bottom. Any inconsistencies would be glaring up next to the straight piping that accented each seat.

To guarantee this symmetry, the pattern was laid out on the leather and stitched at the same time as the foam. It was important to do this step by hand because foam allows the leather to shift easily during the sewing process. A machine is not capable of checking its work. If left unattended, the leather can and will move, requiring the entire piece to be re-stitched, wasting valuable time and expensive leather.

This was a hands-on project where the personal touch made a huge impact in the end. Another example is the odd-shaped headrest, which is wider at the top than the bottom. Stretching and wrapping the leather around the foam shape with the company logo centered without wrinkles or gathers takes time and the care of an expert’s hand.

High quality is found in the details, details that are lost if work is done by a machine.

It Takes A Team

No one person can take credit for the quality of workmanship on these luxurious seats. “It took the entire team to make it happen,” says Niki. “Everyone was excited to tackle a different type of project. We had big discussions about our process, communicated well, and stayed focused.”

No one person can take credit for the quality of workmanship on these luxurious seats. “It took the entire team to make it happen,” says Niki. “Everyone was excited to tackle a different type of project. We had big discussions about our process, communicated well, and stayed focused.”

These seats were a big challenge when compared to the typical aircraft seat. They were labor-intensive, but they also required a high degree of focus to ensure quality and consistency. The starting point came with the seat foam team creating five shapes that were exactly alike. From these shapes, the leather patterns were created and cut from the best parts of the leather. Pattern makers stitched the foam to the leather and cut the patterns. Several team members stitched the pieces together creating inserts and cushions.

Although complicated, the project went smoothly. Other than a few adjustments along the way, they had no major setbacks. Niki is proud of her team. “Everyone took their job seriously and put their best foot forward. We turned out a great product.”

When the final seats were lined up next to each other in the shop, they looked like carbon copies of an original. The careful modeling, precision stitching, and exact construction were worth the extra time and effort it took.

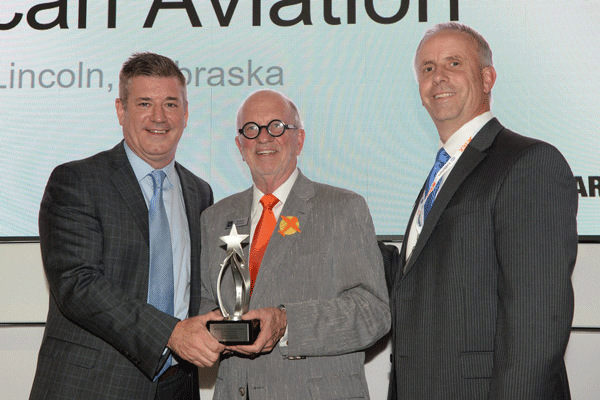

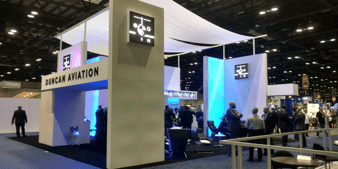

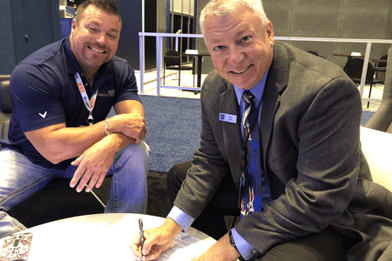

We've heard 'a picture is worth a thousand words.' So we're going to let our NBAA-BACE photos do the talking.

We've heard 'a picture is worth a thousand words.' So we're going to let our NBAA-BACE photos do the talking.

No one person can take credit for the quality of workmanship on these luxurious seats. “It took the entire team to make it happen,” says Niki. “Everyone was excited to tackle a different type of project. We had big discussions about our process, communicated well, and stayed focused.”

No one person can take credit for the quality of workmanship on these luxurious seats. “It took the entire team to make it happen,” says Niki. “Everyone was excited to tackle a different type of project. We had big discussions about our process, communicated well, and stayed focused.”

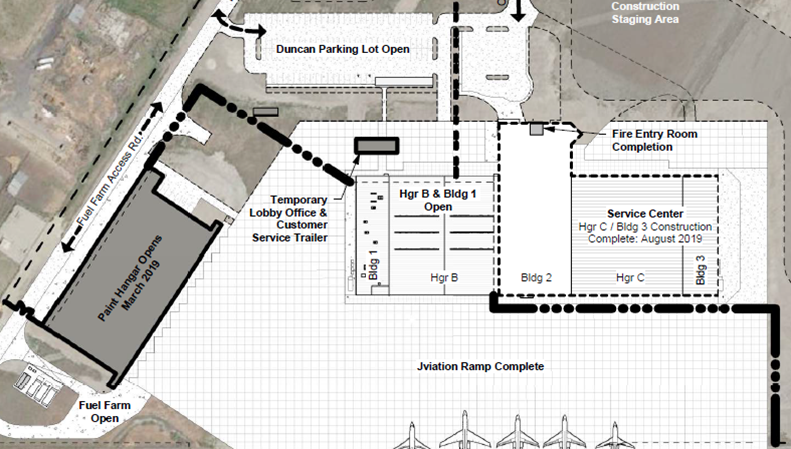

and the entire hangar floor is now in. The Paint Hangar is on track to open in March 2019, and the structural steel is up and being closed in for Hangar C and Building 3 (opening June 2019). The structural steel is also being erected for Building 2 (opening in the first quarter of 2020).

and the entire hangar floor is now in. The Paint Hangar is on track to open in March 2019, and the structural steel is up and being closed in for Hangar C and Building 3 (opening June 2019). The structural steel is also being erected for Building 2 (opening in the first quarter of 2020).

The 14" thick ramp took 35,000 yards of concrete, and 6.5 million pounds of steel.

The 14" thick ramp took 35,000 yards of concrete, and 6.5 million pounds of steel.

Every chance he gets, Todd Duncan attends new employee orientations to talk to the latest Duncan Aviation team members. He impresses upon them the importance of maintaining open and honest communication at all levels.

Every chance he gets, Todd Duncan attends new employee orientations to talk to the latest Duncan Aviation team members. He impresses upon them the importance of maintaining open and honest communication at all levels. Today marks Duncan Aviation's Founder’s Day. Wednesday, August 22, is the 96th birthday of our founder, the late Donald Duncan.

Today marks Duncan Aviation's Founder’s Day. Wednesday, August 22, is the 96th birthday of our founder, the late Donald Duncan.

Chad Doehring, recently named Vice President of Operations for Duncan Aviation’s Provo, Utah, location, has always loved the mountains. Born and raised in Arvada, Colorado, he spent much of his childhood enjoying hiking, skiing, and camping. After he graduated high school, he won a full-ride scholarship to Colorado AeroTech, where he earned his Airframe & Powerplant license.

Chad Doehring, recently named Vice President of Operations for Duncan Aviation’s Provo, Utah, location, has always loved the mountains. Born and raised in Arvada, Colorado, he spent much of his childhood enjoying hiking, skiing, and camping. After he graduated high school, he won a full-ride scholarship to Colorado AeroTech, where he earned his Airframe & Powerplant license. Chad and his wife, Stacey, have relocated to the Provo area. They are excited about the move, especially because of the recreational and community activities the area has to offer. They are also pleased with the friendly people and the way the community has welcomed them with open arms.

Chad and his wife, Stacey, have relocated to the Provo area. They are excited about the move, especially because of the recreational and community activities the area has to offer. They are also pleased with the friendly people and the way the community has welcomed them with open arms. We are the first and only large MRO to achieve this accreditation. I am proud of my team and the company for all the hard work they performed to make it happen.

We are the first and only large MRO to achieve this accreditation. I am proud of my team and the company for all the hard work they performed to make it happen. The IS-BAH process typically takes a couple of years to complete. With our high standards, focus and cross-department collaboration, though, we were able to complete the Stage One accreditation in just five months. This is a huge accomplishment! Thanks to everyone to played a part in developing this competitive advantage for our Line Services.

The IS-BAH process typically takes a couple of years to complete. With our high standards, focus and cross-department collaboration, though, we were able to complete the Stage One accreditation in just five months. This is a huge accomplishment! Thanks to everyone to played a part in developing this competitive advantage for our Line Services. Darrold Comber suspected his search would not be an easy one. His needle? A joystick from a Grumman F6F Hellcat Fighter with working buttons. After an online search showed Duncan Aviation listing the part in stock, he picked up the phone and called Lance Tophoj, Duncan Aviation Parts & Rotables Sales Rep.

Darrold Comber suspected his search would not be an easy one. His needle? A joystick from a Grumman F6F Hellcat Fighter with working buttons. After an online search showed Duncan Aviation listing the part in stock, he picked up the phone and called Lance Tophoj, Duncan Aviation Parts & Rotables Sales Rep. In honor of Summit’s milestone birthday and in memory of Benjamin, Darrold, created a one-of-a-kind handmade cane that featured a Grumman F6F Hellcat joystick as its handle. Two custom-stamped dog tags were added as the finishing touch.

In honor of Summit’s milestone birthday and in memory of Benjamin, Darrold, created a one-of-a-kind handmade cane that featured a Grumman F6F Hellcat joystick as its handle. Two custom-stamped dog tags were added as the finishing touch.

“In all the years I’ve been doing this, only 3 flights have failed,” Randy said. “A Learjet 55 had a hard drive crash and the other two had computer issues with data, so we’ve been pretty accurate and fortunate to have those results.”

“In all the years I’ve been doing this, only 3 flights have failed,” Randy said. “A Learjet 55 had a hard drive crash and the other two had computer issues with data, so we’ve been pretty accurate and fortunate to have those results.”