“I love turning flying machines into eye candy.”

“I love turning flying machines into eye candy.”

—John Stahr, Artist

When aircraft owners come to Duncan Aviation with a paint idea, whether it’s digital camo, Matterhorn white with a stripe or a concept that belongs in a Jackson Pollock exhibit, our team makes it happen.

With a team full of talented artists and detail-oriented paint experts, Duncan Aviation can produce almost any aircraft paint work in-house. Sometimes, though,  projects come up that, due to schedule and workloads, require collaboration with outside artists. When those extra-special projects pop up, Duncan Aviation’s paint team often calls up artist John Stahr.

projects come up that, due to schedule and workloads, require collaboration with outside artists. When those extra-special projects pop up, Duncan Aviation’s paint team often calls up artist John Stahr.

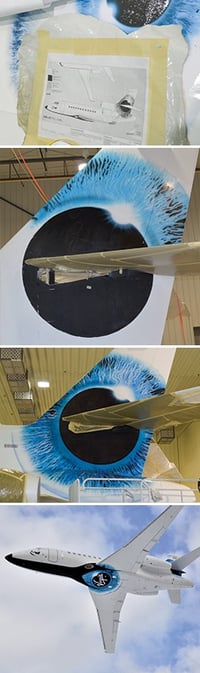

“When we scheduled the paint job for Virgin’s Galactic Girl at our Battle Creek, Michigan, location, we knew John was the extra team member we needed to complete the paint scheme the way we envisioned it,” explains Completions Sales Rep Nate Darlington.

John has 40 years of custom paint experience and can airbrush the most intricate designs. He started in the mid-1970s working on vehicles, adding vans, motorcycles, race team trucks and luxury coaches to his portfolio. In 2003, he started painting aircraft exclusively.

“Painting something unique on a business jet brings me a great deal of satisfaction, especially when I see my creation parked next to the traditional white aircraft with three stripes,” explains John. “I love turning flying machines into eye candy.”

Watch a time-lapse video of Virgin’s Galactic Girl’s paint process.

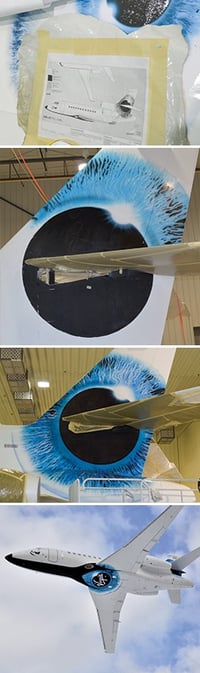

While each airbrushed paint scheme is wildly different, the backend process is fairly standard. For this paint scheme:

- Nate collaborated with Duncan Aviation’s in-house design team to develop a detailed rendering that fit the aircraft. The customer wanted the Dassault Falcon 900EX to mesh well with the rest of Virgin’s aircraft fleet, specifically SpaceShipTwo. Duncan Aviation Designer Lori Browning collaborated with the customer to craft several interpretations that incorporated a handful of SpaceShipTwo characteristics, including the black belly and strategically placed logos.

- John and the paint team created full-scale patterns by projecting layout sketches onto white paper.

- The paint crew prepped a substrate surface for John to transfer the drawings, using his pattern.

- Duncan Aviation’s paint layout team constructed two graphics: one showcasing the evolution of spaceflight and another displaying the Galactic Girl herself.

- Then, the fun began.

“I paint by hand, using spray guns and airbrush. Sometimes I’m very precise with measurements. Other times, I paint by eye. I do whatever it takes to make the final piece turn heads,” says John.

Painting large aircraft like Virgin’s Galactic Girl requires two sets of skills: artistic and physical.

John and the rest of the paint team do a lot of climbing and balancing. Operating a lift or climbing a ladder while wearing fall protection isn’t easy. Sometimes, it’s downright unnerving for an artist who needs a steady hand.

After John completed the Virgin Galactic eye logo on the aircraft’s belly, he added two more to either side of the vertical stabilizer. Duncan Aviation’s paint layout team added graphics to the forward portion of the aircraft, completing the artistic aspects of the paint design.

The paint team added clear coat to preserve the delicate airbrushing and graphics, as well as set off the detailed artwork. They sprayed a urethane clear coat to shield the artwork from extreme flying conditions.

Then, the aircraft entered its final step: the detailing phase. Duncan Aviation’s paint team reviewed every square inch of the aircraft, correcting any minor errors. After buffing the jet one last time, the team delivered the aircraft. With the Galactic Girl, they did so ahead of the original schedule.

“The people at each of Duncan Aviation’s locations must be from special aviation bloodlines or something,” explains John. “They all really care about their work, and they make sure every aircraft they touch has the highest level of attention to detail and quality.”

And that’s why when John and several Duncan Aviation teams collaborate, the customer wins.

Read more from the Duncan Debrief Magazine

The Duncan Debrief free publication is available for aviation enthusiasts around the world through mail and online. To receive the magazine, subscribe here. Have an iPad? Access the magazine through the Duncan Debrief app. Search for Duncan Debrief in Apple’s App Store and download it. Once downloaded, you can receive push notifications each time a new Duncan Debrief magazine is published.

2016 is a special year. It is Duncan Aviation’s 60th year of helping business aircraft operators be safe, efficient and productive. For six decades, customers have asked us for solutions and services. We are celebrating our 60 years by telling the stories about the people of Duncan Aviation who listened and took action.

2016 is a special year. It is Duncan Aviation’s 60th year of helping business aircraft operators be safe, efficient and productive. For six decades, customers have asked us for solutions and services. We are celebrating our 60 years by telling the stories about the people of Duncan Aviation who listened and took action. On a weekly basis, I travel to meet with some of the most interesting and influential people in our industry; individuals who work hard providing leadership for business aviation’s powerful associations and lobbying efforts, key customers who understand the benefits of business aircraft ownership and aviation enthusiasts who simply love to fly. I truly enjoy the people in our industry and the support they have shown us for years.

On a weekly basis, I travel to meet with some of the most interesting and influential people in our industry; individuals who work hard providing leadership for business aviation’s powerful associations and lobbying efforts, key customers who understand the benefits of business aircraft ownership and aviation enthusiasts who simply love to fly. I truly enjoy the people in our industry and the support they have shown us for years. 2016 is a special year. It is Duncan Aviation’s 60th year of helping business aircraft operators be safe, efficient and productive. For six decades, customers have asked us for solutions and services. We are celebrating our 60 years by telling the stories about the people of Duncan Aviation who listened and took action.

2016 is a special year. It is Duncan Aviation’s 60th year of helping business aircraft operators be safe, efficient and productive. For six decades, customers have asked us for solutions and services. We are celebrating our 60 years by telling the stories about the people of Duncan Aviation who listened and took action.

In April 2015, the 61-year-old amphibious aircraft landed at Duncan Aviation’s Lincoln, Nebraska, facility to get fitted with its new interior—or, more accurately, an interior.

In April 2015, the 61-year-old amphibious aircraft landed at Duncan Aviation’s Lincoln, Nebraska, facility to get fitted with its new interior—or, more accurately, an interior.

“I love turning flying machines into eye candy.”

“I love turning flying machines into eye candy.” projects come up that, due to schedule and workloads, require collaboration with outside artists. When those extra-special projects pop up, Duncan Aviation’s paint team often calls up artist John Stahr.

projects come up that, due to schedule and workloads, require collaboration with outside artists. When those extra-special projects pop up, Duncan Aviation’s paint team often calls up artist John Stahr. Read the

Read the