Submitted by Curt Campbell, avionics tech rep

Submitted by Curt Campbell, avionics tech rep

There have been many articles and videos in the Duncan Intelligence over the years, written and produced by tech reps and technicians at Duncan Aviation about the proper care and maintenance of an aircraft gyro.

However, it wasn't long ago that I got a call from an operator who was having precession errors and failures to erect on his gyro. It didn't take long for me to figure out that the cause of his issue was the result of the gyro not being allowed enough time (20 minutes) to spool-down before the aircraft was moved.

He stated his crew wasn't aware of this required spool-down time. This oversight unfortunately required a complete overhaul of the gyro, costing several thousand dollars.

Time for another reminder..

I encourage you to share this information with all personnel tasked with aircraft movement/maintenance in your company. Below are links for your use. You can bookmark them for future reference.

Gyro Handling Care

(VIDEO) How To Care For Your Aircraft Gyro: Proper Spool-Down Time

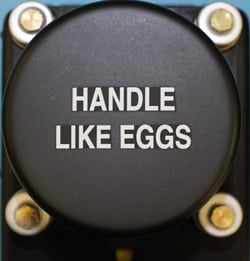

(VIDEO) How to Care for Your Aircraft Gyro: Handle Like Eggs

Proper Handling of Your Gyroscope

Gyro Shipping Procedures

Critical Shipping Procedures When Transporting An Aircraft Gyroscope

Critical Shipping Procedures: Two-Box Shipping Method

Gyro Maintenance

What are Electrolytic Leveling Switches and Why Should You Care?

What Happens During an L-3 Vertical Gyro Overhaul?

Recommended Service Bulletins for L-3 Vertical Gyros

Recommended Service Bulletins for Honeywell Vertical and Directional Gyros

What Happens During an L-3 Vertical Gyro Overhaul?

Gyro Exchange Units

Honeywell Aerospace VG14A Gyro SPEX Exchanges

Duncan Intelligence

You can get technical articles like these in your in-box every month by subscribing to the Duncan Aviation Duncan Intelligence.