The doors to NBAA 2016 were barely open an hour before there was already a flurry of activity in Duncan Aviation’s booth.

Hundreds were on hand as representatives from Rolls-Royce and Duncan Aviation joined in a signing ceremony to officially recognize Duncan Aviation being named to Rolls-Royce’s network of Authorized Service Centers for its CorporateCare ® customers.

(L to R) Aaron Hilkemann, Duncan Aviation President, Kimberly Rubush, Rolls-Royce Services Manager, Andrew Robinson, Rolls-Royce Deputy SVP Services—Aerospace, Robert Duncan, Duncan Aviation Chairman Emeritus, Jörn Lindstädt, Rolls-Royce, Head of Aircraft Availability Centre, Business Aviation, Steve Gade, Duncan Aviation VP Marketing & New Business Development, and Tom Burt, Duncan Aviation EVP/COO, BTL Operations.

The contract authorizes all of Duncan Aviation’s MRO (maintenance, repair, and overhaul) facilities in Battle Creek, MI, Lincoln, NE, and Provo, UT, and 14 Engine Rapid Response locations to service AE 3007A, BR710 A1/C4/A2, as well as, Tay 611-8/8C engines.

For several years, Duncan Aviation has been supporting Rolls-Royce powered aircraft around the country with line maintenance so many of our technicians are already factory trained for line maintenance and borescope inspection. Beginning the first quarter of 2017, Duncan Aviation will begin providing warranty claim processing and on-site parts, along with in-house engine maintenance on-site parts and warranty claim processing for all Gulfstream G500/G550, G400/G450, G300/G350, Bombardier Global Express and Global 5000/6000, Embraer Legacy 600, and 650 operators enrolled on Rolls-Royce Corporatecare.

“This is a huge benefit to our customers who already rely upon us for airframe maintenance and inspection,” says Duncan Aviation Airframe Service Sales Rep Brad Lennemann. “Now they can rely upon us to manage all of their warranty maintenance, airframe and engine.”

If you are at the 2016 NBAA show in Orlando, Florida, we’d love you to stop by our booth (#3126) and say hi.

For more Duncan Aviation NBAA announcements, visit www.DuncanAviation.aero/News.

The new flight deck provides operators with an ADS-B mandate solution while enhancing their ownership and flying experience. The Pro Line Fusion upgrade replaces the factory-installed portrait displays with larger 14.1-inch landscape touchscreen primary flight displays. The new system includes intuitive, touch-interactive maps, and easy-to-use icons, giving the pilot the ability to control items on the screen through touch. Also, it eliminates the need for Flight Management System (FMS) control display units originally installed in the pedestal.

The new flight deck provides operators with an ADS-B mandate solution while enhancing their ownership and flying experience. The Pro Line Fusion upgrade replaces the factory-installed portrait displays with larger 14.1-inch landscape touchscreen primary flight displays. The new system includes intuitive, touch-interactive maps, and easy-to-use icons, giving the pilot the ability to control items on the screen through touch. Also, it eliminates the need for Flight Management System (FMS) control display units originally installed in the pedestal. Within 24 hours of

Within 24 hours of  I’ve been in this industry for a LOT of years and talked to even more people. But it never gets old to hear appreciation from your peers. It’s having friends and business associates like these that continued to drive us towards expanding Duncan Aviation Turbine Engine Services knowing full well that if "we build it" they may come.

I’ve been in this industry for a LOT of years and talked to even more people. But it never gets old to hear appreciation from your peers. It’s having friends and business associates like these that continued to drive us towards expanding Duncan Aviation Turbine Engine Services knowing full well that if "we build it" they may come. No matter what devilish ghouls come your way this haunted Halloween, rest assured that we at Duncan Aviation have your back (and wings and landing gear and engines and interior and pretty much anything else you need us to cover).

No matter what devilish ghouls come your way this haunted Halloween, rest assured that we at Duncan Aviation have your back (and wings and landing gear and engines and interior and pretty much anything else you need us to cover).

“I was part of something remarkably special,” says Don. “The Duncan Aviation way epitomizes excellence in the aviation industry—the company simply did everything right. Duncan Aviation treats its customers and employees with great respect and has created a culture and friendly environment that bring out the very best in everyone.”

“I was part of something remarkably special,” says Don. “The Duncan Aviation way epitomizes excellence in the aviation industry—the company simply did everything right. Duncan Aviation treats its customers and employees with great respect and has created a culture and friendly environment that bring out the very best in everyone.” The board was created due to our commitment to our customers and to improve service. It represents various business jet stakeholders who provide a broad perspective of the industry. Board members play a big role in exchange of information about important industry and service issues. This dialogue is extremely important to us as it depends heavily on ECAB’s input when making critical decisions related to the business.

The board was created due to our commitment to our customers and to improve service. It represents various business jet stakeholders who provide a broad perspective of the industry. Board members play a big role in exchange of information about important industry and service issues. This dialogue is extremely important to us as it depends heavily on ECAB’s input when making critical decisions related to the business.

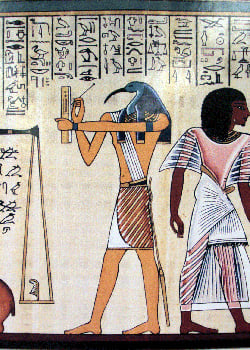

Hanging in Duncan Aviation's Calibration Services Lab is a poster about the History of the Egyptian Cubit. It depicts the beginning of tool calibration more than 5,000 years ago. Many similarities to modern calibrations still remain.

Hanging in Duncan Aviation's Calibration Services Lab is a poster about the History of the Egyptian Cubit. It depicts the beginning of tool calibration more than 5,000 years ago. Many similarities to modern calibrations still remain.