“By standing on the shoulders of giants,” that is how Bob Tooker credits any success he has had.

The Charles Taylor Master Mechanic Award is named in honor of Charles Taylor, the first aviation mechanic in powered flight. Taylor served as the Wright brothers' mechanic and is credited with designing and building the engine for their first successful aircraft. The award recognizes the lifetime accomplishments of senior mechanics.

The Charles Taylor Master Mechanic Award is named in honor of Charles Taylor, the first aviation mechanic in powered flight. Taylor served as the Wright brothers' mechanic and is credited with designing and building the engine for their first successful aircraft. The award recognizes the lifetime accomplishments of senior mechanics.

As a farm kid from Silver Creek, NE, Bob's giants included his father and Uncle Norman who, he says, “must have saw something in me because they always allowed me to tag along and spent so much time teaching and showing me how things worked.” While on the farm, active in 4-H and Junior Leadership, he always had his eyes in the sky. From a young age he had a love of airplanes, and knew he wanted to get involved but didn’t know how.

Bob joined the U.S. Navy in 1967 and was sent to Avionics School in Memphis, TN, after he tested very high with an aptitude for aviation. His first duty station was in Pensacola, FL, with Helicopter Training Squadron 8 (HT8) as a Line avionics tech/Quality inspector. Then on to Naval Air Station Mirimar (San Diego) with Fighter Squadron 51 (VF51) with a side trip to Vietnam. He went on to earn his A&P certificate at Spartan School of Aeronautics in Tulsa, OK.

In 1974, at a time when there were only 17 aircraft mechanics, Bob came to work at Duncan Aviation working on early model Learjets, Bonanzas, Barons, and King Air aircraft. It wasn’t long before he began leading his own teams through major inspections. His first job as lead mechanic was for the 10 year, 10,000 hour demates inspection on a Learjet 23 and 24. He admits this first leadership run was a bit intimidating, but when he went on his first test flight with Harry Barr, an aviation legend in his own right, doing test stalls and wing checks, it pretty much sealed the deal for Bob on his love for aviation. He was in it for the long haul.

One of his favorite projects was the disassembly, transportation, and reassembly of a Learjet 35 that can be seen hanging in Terminal 3 of the Denver International Airport.

He encountered more giants in his career at Duncan Aviation. Giants like Joe Huffman Sr., and Bernard Michael, both previous Charles Taylor Master Mechanic Award winners, and Kent Kussatz. According to Bob, Joe was the best troubleshooter he ever saw. Bernard was slow, steady, and calm in his work, a real mentor. And Kent put a lot of trust in him that helped his confidence grow. Bob advanced quickly to other leadership roles including shop supervisor.

It was in 1984 he was asked to be on the ground floor in the development of a new division of Duncan Aviation, AVPAC (Aviation Parts, Avionics, & Components), that would manage an extensive inventory of aircraft avionics and parts available for sale. Bob traveled across the country buying old or wrecked aircraft to be parted out or inspecting potential parts consignments, helping build the inventory from scratch. For the remainder of his career, Bob wore many hats, including inventory quality control, and sales rep. He decided after 43 years, it was time to retire.

He wife Cheryl has been by his side through most of his career in aviation. He met her on a blind date set up by an old classmate. They married in April of 1972 and together, have two children and four grandchildren.

He wife Cheryl has been by his side through most of his career in aviation. He met her on a blind date set up by an old classmate. They married in April of 1972 and together, have two children and four grandchildren.

Bob has a lot of gratitude for Robert Duncan, Chairman Emeritus Duncan Aviation. “I always felt encouraged and empowered by the trust Robert in me early in my career. I want to thank him for the fun ride.”

Everyone at Duncan Aviation laughed along with most of the rest of the business aviation industry on April Fool’s Day when the spoof press release claimed the deadline for the Automatic Dependent Surveillance-Broadcast (ADS-B) mandate had been extended until 2040. Not long after the laughter died down, though, the FAA reiterated that the agency’s deadline will not change, saying, “We have a sense of humor, too, but an April Fool’s joke that the FAA is extending the ADS-B deadline is just that.”

Everyone at Duncan Aviation laughed along with most of the rest of the business aviation industry on April Fool’s Day when the spoof press release claimed the deadline for the Automatic Dependent Surveillance-Broadcast (ADS-B) mandate had been extended until 2040. Not long after the laughter died down, though, the FAA reiterated that the agency’s deadline will not change, saying, “We have a sense of humor, too, but an April Fool’s joke that the FAA is extending the ADS-B deadline is just that.” Because time flies and aircraft without ADS-B probably won’t after the deadline, Duncan Aviation would like to remind its customers that the company has numerous certified paths to upgrade equipment to comply with the FAA’s ADS-B mandate. Duncan Aviation holds (or has access to) 42 STCs for dozens of aircraft models.

Because time flies and aircraft without ADS-B probably won’t after the deadline, Duncan Aviation would like to remind its customers that the company has numerous certified paths to upgrade equipment to comply with the FAA’s ADS-B mandate. Duncan Aviation holds (or has access to) 42 STCs for dozens of aircraft models.

Sean is an Inspection Unit Member for Duncan Aviation’s ODA and Project Planner for the company’s highly regarded Engineering & Certification Services Alterations Planning Team. With more than 20 years of experience at Duncan Aviation, four years in the United States Navy as an avionics electrician, a degree in avionics from Spartan College of Aeronautics and Technology in Tulsa, Oklahoma, and a certified A&P maintenance tech, Sean is fully prepared to provide information and answer questions about engineering and certification.

Sean is an Inspection Unit Member for Duncan Aviation’s ODA and Project Planner for the company’s highly regarded Engineering & Certification Services Alterations Planning Team. With more than 20 years of experience at Duncan Aviation, four years in the United States Navy as an avionics electrician, a degree in avionics from Spartan College of Aeronautics and Technology in Tulsa, Oklahoma, and a certified A&P maintenance tech, Sean is fully prepared to provide information and answer questions about engineering and certification. .jpg?width=600&name=1Q2A1592%20(Small).jpg)

.jpg?width=603&height=402&name=1Q2A1701%20(Small).jpg)

.jpg?width=603&height=402&name=1Q2A1747%20(Small).jpg)

The Charles Taylor Master Mechanic Award is named in honor of Charles Taylor, the first aviation mechanic in powered flight.

The Charles Taylor Master Mechanic Award is named in honor of Charles Taylor, the first aviation mechanic in powered flight.  He wife Cheryl has been by his side through most of his career in aviation. He met her on a blind date set up by an old classmate. They married in April of 1972 and together, have two children and four grandchildren.

He wife Cheryl has been by his side through most of his career in aviation. He met her on a blind date set up by an old classmate. They married in April of 1972 and together, have two children and four grandchildren.

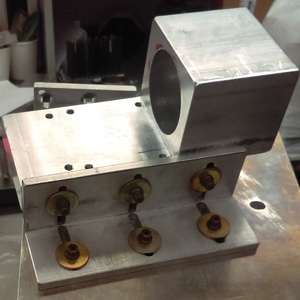

Most recently, Lead Machinist Mark Leppky and Master Machinist Todd Hoffman took the tooling on the road. The end-customer, an air ambulance operator based in South America, needed the quickest repair possible.

Most recently, Lead Machinist Mark Leppky and Master Machinist Todd Hoffman took the tooling on the road. The end-customer, an air ambulance operator based in South America, needed the quickest repair possible. Duncan Aviation and its multi-shop capabilities can save you a whole lot of money.

Duncan Aviation and its multi-shop capabilities can save you a whole lot of money.

.jpg?t=1513285766908&width=100&height=125&name=Kruce,%20Scott%20(Small).jpg)

Today, buyers who are in the market for a new aircraft echo the sentiments of their terrestrial home-buyers in that they want a move-in-ready, or take-to-the-skies-ready, aircraft.

Today, buyers who are in the market for a new aircraft echo the sentiments of their terrestrial home-buyers in that they want a move-in-ready, or take-to-the-skies-ready, aircraft. “Even with the small number of buyers who see zero value for themselves in having a connected aircraft, we point out that installing internet adds at least 50% of the installation cost to the aircraft resale value,” says Roth. “The majority of buyers looking for aircraft today want an internet connection.”

“Even with the small number of buyers who see zero value for themselves in having a connected aircraft, we point out that installing internet adds at least 50% of the installation cost to the aircraft resale value,” says Roth. “The majority of buyers looking for aircraft today want an internet connection.”