In the USAF (United States Air Force), Bob Hazy frequently flew into Lowry Air Force Base in Denver, Colorado and knew he’d eventually like to live in the state. He also knew from his dealings with Duncan Aviation, that it was an upstanding company that conducted business with integrity. He could see himself working there after retiring from the USAF.

Once he retired in 1998, however, Bob initially went to work for an aviation company in Wichita.

“In the Air Force, I worked on avionics, so after retiring, I started working as an avionics technician at an avionics shop in Wichita,” says Bob.

Within two years, he was working for Duncan Aviation at the Fort Lauderdale, Florida, avionics satellite facility. While working with Dave Molsberry, the shop frequently had a surplus of work, so techs from Duncan Aviation’s Denver facility helped out in Florida.

When a position opened at the Denver facility in 2004, Bob left the sun and sand of Florida behind and moved his family to Denver. He worked for Matt Nelson, who was manager of the Denver shop at the time. When Matt was promoted to Manager of Satellite Operations in 2008, Bob took over as Manager of the Duncan Aviation Denver satellite avionics facility.

Bob’s opinion of the company hasn’t changed much in the 16 years he’s worked for Duncan Aviation.

“It’s a great company to work for, and we have an incredible mix of people here in Denver,” says Bob. “In fact, I think we’re the best satellite because of the 14 people who work at this shop . . . well, 12 plus V12 and Beau in Broomfield. The atmosphere of our shop is so special that when anyone comes here to help us out, they want to stay here, too!”

V12, as Bob has nicknamed him, is Chris Vadeboncoeur, and he works in Broomfield at the Rocky Mountain Metropolitan Airport. Broomfield is about 35 miles northwest of the Centennial Airport. The shop does mostly line work, and crews from the Denver satellite shop help with installations. Chris takes care of the airplanes from the northern airports in Fort Collins and Greeley, and he even services some from Casper, Wyoming, and Scottsbluff, Nebraska.

During ski season from December 1 through April 30, Roy (Beau) Hawkins works at the Vail Valley Jet Center in Gypsum, Colorado, servicing planes for skiers. He joins V12 at the Broomfield facility from May 1 through November 30.

As much as Bob values the technical skills and expertise of his team, he knows that his facility works as well as it does because everyone wants to be there, they value their relationships with customers and fellow team members, and they all love the environment and community, too.

“Everything we do takes teamwork and respect,” says Bob. “We’re located at a busy airport in a busy part of the country, and we work on everything from small, experimental aircraft all the way up to Globals. Although this is Falcon country, and we see a lot of 900s, 2000s, 7Xs, and 50s, we are also starting to see more Gulfstreams and Hawkers, too.”

Erik Benson, Ken Smith, Kim Owen, John Sims, Wayne Sand, Thomas Gauna, Chris Demarest, Sean Macoomb, Matt Whitney, Bob Hazy. Not Pictured: Rodney Weaver, Charles Anderson, Chris Vadeboncoeur, Beau Hawkins

The Denver avionics satellite maintains the avionics systems of general aviation, business charter, and even government aircraft. There are roughly 600 small reciprocating aircraft and 250 jet aircraft that make their home at the Centennial Airport in Denver, where the Duncan Aviation avionics satellite facility is located. Bob and his team work on aircraft located along the front range of the Rocky Mountains, from Albuquerque, New Mexico, to Bozeman, Montana.

“I couldn’t be more proud of the team and the relationships that the Denver satellite has built,” says Matt Nelson. “They make our jobs a lot easier.”

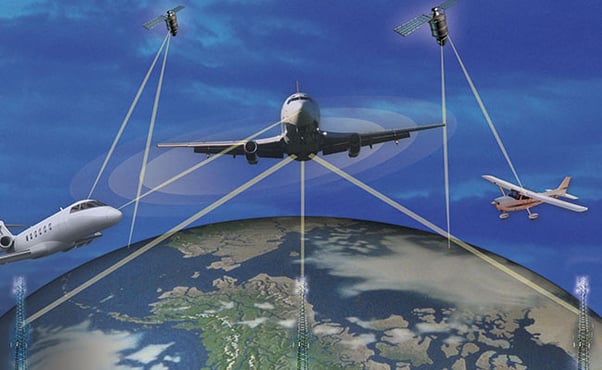

More importantly for the customers, the techs from the Denver satellite facility usually travel to customers’ hangars to do their repair, maintenance, and installation work. The shop focuses primarily on avionics line work and avionics installations. They’ve been installing ADS-B out on a lot of smaller aircraft and are just starting to see ADS-B installations on larger aircraft.

“Typically, we see the Gogo Biz High Speed Data installations to Garmin stacks and FMS upgrades. We’ve done a lot of TCAS 7.1, too,” says Bob. “Lots of our customers travel outside of the United States, so they’re installing the mandated NextGen equipment.”

Bob says that brief description doesn’t begin to capture the range of work they do, though. They also work directly with some of our vendors like Gogo Biz and help with their STCs.

“We recently modified the Gogo Biz Challenger so they could test new equipment in the future,” says Bob. “A great example of our quality was when we did a complete upgrade of an FMS for a customer who was taking his aircraft out of the country to New Zealand. After 10 years of flawless operation, the DOM sent Matt Nelson a letter that said, ‘You guys talk about guaranteeing your work for the life of the aircraft, and you can do that because your work lasts that long! We just sold that aircraft squawk-free.’”

An abundance of sunshine and blue sky was on hand for the Duncan Aviation Denver Satellite Avionics customer appreciation BBQ at the Centennial Airport in Englewood, CO. Hundreds of customers from the area enjoyed great food.

Honeywell has released SB (Service Bulletin) AS 907-76-9021 Rev 0 dated May 13, 2016, regarding the possibility of water entering the ECUs (Electronic Control Unit) after the aircraft is parked in the rain for an extended length of time. This may lead to unscheduled maintenance and expense, aircraft dispatch delays, Loss of Thrust Control (LOTC) events and the possibility for inflight shut downs.

Honeywell has released SB (Service Bulletin) AS 907-76-9021 Rev 0 dated May 13, 2016, regarding the possibility of water entering the ECUs (Electronic Control Unit) after the aircraft is parked in the rain for an extended length of time. This may lead to unscheduled maintenance and expense, aircraft dispatch delays, Loss of Thrust Control (LOTC) events and the possibility for inflight shut downs.

Duncan Aviation avionics installation technicians this week turned power on to the Rockwell Collins Pro Line Fusion® flight deck upgrade being installed and certified in the Citation CJ3. Duncan Aviation avionics technicians have been installing and testing the equipment since mid-May. The airplane is expected to fly in the next few weeks and be certified by the end of 2016.

Duncan Aviation avionics installation technicians this week turned power on to the Rockwell Collins Pro Line Fusion® flight deck upgrade being installed and certified in the Citation CJ3. Duncan Aviation avionics technicians have been installing and testing the equipment since mid-May. The airplane is expected to fly in the next few weeks and be certified by the end of 2016.

Since the first Pentium was installed in Honeywell’s Primus 1000 system, OEMs have relied on laptops for maintenance functions. The latest generations of aircraft are delivered with dedicated laptops. Once the aircraft departs the completion center though, you often find that you are on your own to maintain this new (and sometimes unfamiliar) addition to your flight department. Knowing that a failed laptop can wreak havoc, it is wise to take measures to ensure the best possible service life from your maintenance laptops. The following represents some guidelines that may assist in prolonging the service life of your equipment.

Since the first Pentium was installed in Honeywell’s Primus 1000 system, OEMs have relied on laptops for maintenance functions. The latest generations of aircraft are delivered with dedicated laptops. Once the aircraft departs the completion center though, you often find that you are on your own to maintain this new (and sometimes unfamiliar) addition to your flight department. Knowing that a failed laptop can wreak havoc, it is wise to take measures to ensure the best possible service life from your maintenance laptops. The following represents some guidelines that may assist in prolonging the service life of your equipment.

Hundreds turned out for the GAMA Michigan Jobs Rally held last Friday at Duncan Aviation in Battle Creek, MI, to recognize the importance of aviation and its contributions to our communities and state.

Hundreds turned out for the GAMA Michigan Jobs Rally held last Friday at Duncan Aviation in Battle Creek, MI, to recognize the importance of aviation and its contributions to our communities and state.

Technology is amazing. Most pilots and flight planners use smart phones and iPads for everything from researching FBO stops to finding a great caterer. But several are still using floppy disks to update the on-aircraft navigation database. That’s right. Floppy disks.

Technology is amazing. Most pilots and flight planners use smart phones and iPads for everything from researching FBO stops to finding a great caterer. But several are still using floppy disks to update the on-aircraft navigation database. That’s right. Floppy disks. If you want to see an angry passenger, tell him or her you have Wi-Fi and then have it not work. Engines and altimetry do not matter; the only thing that really matters is the lack of internet service, because it is so immediately in front of the client. For that reason alone, I encourage you to carefully consider who will be performing your aircraft Wi-Fi installation. Following are six things to consider when selecting that installer.

If you want to see an angry passenger, tell him or her you have Wi-Fi and then have it not work. Engines and altimetry do not matter; the only thing that really matters is the lack of internet service, because it is so immediately in front of the client. For that reason alone, I encourage you to carefully consider who will be performing your aircraft Wi-Fi installation. Following are six things to consider when selecting that installer.  It is essential that you are able to provide your passengers with the best system possible. Ask about the security measures the avionics installer is familiar with and has installed in the past. Understand how the installation will work for different services, such as phone and datalink services. Your company’s computer specialists may have to work with the avionics installer to ensure everything is set up properly. If the installer appears unfamiliar with troubleshooting or satcom registration procedures, do not use them. I have assisted many clients with troubleshooting and redoing internet installations that were not completed properly.

It is essential that you are able to provide your passengers with the best system possible. Ask about the security measures the avionics installer is familiar with and has installed in the past. Understand how the installation will work for different services, such as phone and datalink services. Your company’s computer specialists may have to work with the avionics installer to ensure everything is set up properly. If the installer appears unfamiliar with troubleshooting or satcom registration procedures, do not use them. I have assisted many clients with troubleshooting and redoing internet installations that were not completed properly.  Ever put together a 1,000 piece puzzle? How about one with no straight-edges or picture on the box? What if you only had a couple of hours to finish and the pieces kept changing shape? Sounds a little daunting, if not impossible doesn’t it. Yet this is a daily scenario at Duncan Aviation.

Ever put together a 1,000 piece puzzle? How about one with no straight-edges or picture on the box? What if you only had a couple of hours to finish and the pieces kept changing shape? Sounds a little daunting, if not impossible doesn’t it. Yet this is a daily scenario at Duncan Aviation.

ADS-B Out

ADS-B Out