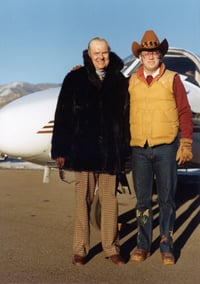

As mentioned in Part I, Robert’s father, Donald Duncan, founded Duncan Aviation in 1956 and this year, Duncan Aviation celebrates 60 years. Now read the rest of the story of how Robert’s vision transitioned the small, family business from its modest beginnings into a company with a respected presence around the world.

As mentioned in Part I, Robert’s father, Donald Duncan, founded Duncan Aviation in 1956 and this year, Duncan Aviation celebrates 60 years. Now read the rest of the story of how Robert’s vision transitioned the small, family business from its modest beginnings into a company with a respected presence around the world.

You can read Tribute To J.Robert Duncan, Part I here

Parts Consignment

Don Fiedler, now Manager of New Business Development for Components, joined the 10-year-old company in 1966 as the fourth member of the very new avionics team. The team repaired and installed avionics equipment on Bonanzas, Barons, and King Airs, and they also did some work on Harry’s helicopters.

As the industry started shifting from primarily piston engines to turbines, Robert saw the surplus parts for the older prop planes just sitting on shelves, and he surmised that there were probably FBOs around the country that had similar investments in unmoving parts. He envisioned a program where companies would send Duncan Aviation their surplus parts and, based on very new, barely known computer networking—a precursor of today’s Internet—Duncan Aviation would create an inventory of the parts and sell them on consignment. This vision became AVPAC (Parts & Rotables today) in the early 1980s.

“I've had the opportunity to work with all four generations. Donald in the early days, then Robert, and now Todd and his sons,” says Project Manager Howard Nitzel. “Robert always had good people to run the day-to-day operations for him. He would be looking at the future, always four or five years out, and willing to try new things. AVPAC is a classic example—a parts support services. It was kind of a pipe dream, and it really took off into a whole industry. Robert was a true visionary, made the company grow, and took care of everyone and their families. He’s a true businessman in every sense of the word.”

“I've had the opportunity to work with all four generations. Donald in the early days, then Robert, and now Todd and his sons,” says Project Manager Howard Nitzel. “Robert always had good people to run the day-to-day operations for him. He would be looking at the future, always four or five years out, and willing to try new things. AVPAC is a classic example—a parts support services. It was kind of a pipe dream, and it really took off into a whole industry. Robert was a true visionary, made the company grow, and took care of everyone and their families. He’s a true businessman in every sense of the word.”

Don Fiedler explains that Robert’s vision was to establish a network, collect the parts, set fair prices, and ship them out to buyers the day they ordered.

“He wanted to make it easy to find parts and to get a fair price for them,” says Don. “And he wanted to make sure the inventory was meticulously maintained so we never claimed to have parts we didn’t. ‘First in, first out,’ was Robert’s rule.”

Robert met with Bob McCammon (now manager of Aircraft Sales), Bob Tooker (Senior Sales Rep/Quality Control for Parts & Rotables Sales), Larry Stewart (former Senior Rotables Manager who retired in January after 43 years with Duncan Aviation), and Don Fiedler and explained his idea to get Duncan Aviation into the parts consignment business.

“It was a wonderful thing to work for that man,” says Don. “I’ve always looked up to Robert. I genuinely know him and really respect and like him. The word I most associate with Robert is ‘visionary.’ He surrounded himself with people who could take his ideas and run with them. And, to his credit, although the ideas were his, he always gave us free rein to make his dreams a reality.”

The Satellite Network

Once AVPAC was up and running, Robert again approached Don with an idea. This time, Robert told Rick Whitesell and Don of an experience he and his wife Karen had at a Lincoln’s Hovland-Swanson department store.

“Karen was trying on shoes, and as I waited, I talked to the manager of the shoe department,” says Robert. “He told me he worked for a national shoe company. He said, ‘We specialize in shoes; we just lease this space.’ This got me thinking, ‘How could Duncan Aviation, with our expertise in avionics, expand that around the country?’”

One of Duncan Aviation’s greatest assets has always been its employees. Robert knew there were talented, experienced, knowledgeable technicians in Lincoln, hundreds if not thousands of miles away from where the avionics were that needed servicing.

One of Duncan Aviation’s greatest assets has always been its employees. Robert knew there were talented, experienced, knowledgeable technicians in Lincoln, hundreds if not thousands of miles away from where the avionics were that needed servicing.

“We joke that the avionics satellites are Robert’s five-minute idea that exploded,” says Don. “He said, ‘How ‘bout this idea? We lease space at established, respected FBOs around the country and put in two-man avionics shops. We keep it simple—do simple stuff in the field and continue to have the complex stuff sent to Lincoln. And we offer free loaners and free tech support.’ That was it!”

As a result of Robert’s “five-minute idea,” Duncan Aviation now has more than 20 avionics satellite shops located at busy airports around the country. Not only do our customers drop into these facilities for quick repairs, but also they can schedule complex installations, including upgrades to avionics that satisfy the NextGen mandates.

Robert credits Don for the success of the program. “It was my concept, but Don ran with it, and now Matt is managing all of them,” says Robert.

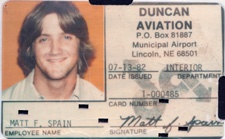

Matt is Matt Nelson, Manager of Satellite Operations. He started at Duncan Aviation in 1987 when he was 18 years old, and it was his first full-time job.

“It was summertime, and Todd Duncan and I were in the warehouse washing cars and airplanes,” laughs Matt. “We were about the same age, and we worked hard.”

As someone who has worked at Duncan Aviation for 29 years, Matt is a member of an exclusive club called Silver Wings.

Silver Wings

Silver Wings is a club that Robert created to celebrate employees who have worked at Duncan Aviation for 25 years or more. Because silver commemorates a 25th anniversary, the group that worked with Robert to establish the club chose Silver Wings as its name.

“It’s a way to recognize all of the many contributions our steadfast, loyal, dedicated employees have made in their tenure here. Many of them have been here far longer than 25 years, too, including Don Fiedler. This year, he’ll celebrate his 50th year with the company,” says Robert. “The Silver Wings employees, about 300 of them now, are the core of what Duncan Aviation is about, and they’re the reason so many of our customers can call Duncan Aviation and talk to the same person they’ve dealt with for 25 years or more. It means so much in our industry, and it means so much to us as a company, too.”

Those employees say the same thing about Robert Duncan and Duncan Aviation

Those employees say the same thing about Robert Duncan and Duncan Aviation

“This company has been my life, mostly because of how the Duncan family has always cared for their employees,” says Don. “It’s a company built on integrity, and I’ve always felt privileged to be a part of something so special. It was such an adventure to get hired on at such a young, exciting place, and I’ve been here to see it grow and become the respected company it is today.”

Todd Duncan, too, is a member of the Silver Wings club, as he has been working at Duncan Aviation for 28 years.

Robert’s Son, Todd Duncan

Todd has been Chairman of Duncan Aviation since 2007, and he’s seen the company ride the waves, the highs and lows, of the business aviation industry.

Todd has been Chairman of Duncan Aviation since 2007, and he’s seen the company ride the waves, the highs and lows, of the business aviation industry.

“One thing I’ve always admired my Dad for is what he brought to the business every single day, regardless of what we were facing, and that’s his optimistic spirit. He’s always able to look to and find brighter days,” says Todd. “He’s a tremendously forward-looking man, and he’s always so positive. He cares deeply about our employees and our customers. He’s the kind of man who inspires others to do their best, too.”

Todd agrees with what Robert calls the immeasurable value of the employees at Duncan Aviation. Father and son are keenly aware of the network of support they have created and developed at Duncan Aviation.

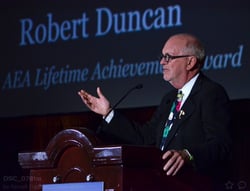

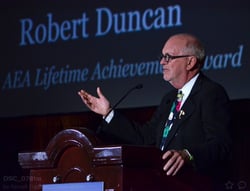

Yesterday, at the annual AEA convention in Orlando, Florida, Robert was given a life-time achievement award, recognizing his contributions to the aviation industry and acknowledging everything he’s done at Duncan Aviation in the last 60 years.

Yesterday, at the annual AEA convention in Orlando, Florida, Robert was given a life-time achievement award, recognizing his contributions to the aviation industry and acknowledging everything he’s done at Duncan Aviation in the last 60 years.

“I couldn’t have done it alone. Everybody out there is doing the work every day—turning the wrenches, fixing the avionics, selling something, or providing support in accounting,” says Robert. “It takes everyone to make this company succeed.”

January 1, 2020 seems like a long way off, but if you remember previous FAA mandates the industry experienced huge backlogs because there simply was not enough hangar space to accommodate the rush of owner/operators who needed to get their aircraft into complaince. Remember the scheduling difficulties with RVSM (Reduced Vertical Separation Minimum)? You don’t? Refresh your memory here. (Remembering the RVSM Crunch)

January 1, 2020 seems like a long way off, but if you remember previous FAA mandates the industry experienced huge backlogs because there simply was not enough hangar space to accommodate the rush of owner/operators who needed to get their aircraft into complaince. Remember the scheduling difficulties with RVSM (Reduced Vertical Separation Minimum)? You don’t? Refresh your memory here. (Remembering the RVSM Crunch) The Duncan Aviation ADS-B Splot Program allows you to buy a slot to reserve a confirmed date and hangar space for your aircraft at one of our Satellite Avionics Shops. The deposit will will applied to the ADS-B installation when you arrive.

The Duncan Aviation ADS-B Splot Program allows you to buy a slot to reserve a confirmed date and hangar space for your aircraft at one of our Satellite Avionics Shops. The deposit will will applied to the ADS-B installation when you arrive.

Today, Duncan Aviation opens a new office at the San Antonio International Airport in Texas. In an effort to position our skilled avionics technician in closer proximity to customers, Greg Ashpaugh, is moving to San Antonio and will be the Manager of the new work-away location.

Today, Duncan Aviation opens a new office at the San Antonio International Airport in Texas. In an effort to position our skilled avionics technician in closer proximity to customers, Greg Ashpaugh, is moving to San Antonio and will be the Manager of the new work-away location.

Captain Per Alkaersig

Captain Per Alkaersig  As mentioned in

As mentioned in  “I've had the opportunity to work with all four generations. Donald in the early days, then Robert, and now Todd and his sons,” says Project Manager Howard Nitzel. “Robert always had good people to run the day-to-day operations for him. He would be looking at the future, always four or five years out, and willing to try new things. AVPAC is a classic example—a parts support services. It was kind of a pipe dream, and it really took off into a whole industry. Robert was a true visionary, made the company grow, and took care of everyone and their families. He’s a true businessman in every sense of the word.”

“I've had the opportunity to work with all four generations. Donald in the early days, then Robert, and now Todd and his sons,” says Project Manager Howard Nitzel. “Robert always had good people to run the day-to-day operations for him. He would be looking at the future, always four or five years out, and willing to try new things. AVPAC is a classic example—a parts support services. It was kind of a pipe dream, and it really took off into a whole industry. Robert was a true visionary, made the company grow, and took care of everyone and their families. He’s a true businessman in every sense of the word.” One of Duncan Aviation’s greatest assets has always been its employees. Robert knew there were talented, experienced, knowledgeable technicians in Lincoln, hundreds if not thousands of miles away from where the avionics were that needed servicing.

One of Duncan Aviation’s greatest assets has always been its employees. Robert knew there were talented, experienced, knowledgeable technicians in Lincoln, hundreds if not thousands of miles away from where the avionics were that needed servicing. Those employees say the same thing about Robert Duncan and Duncan Aviation

Those employees say the same thing about Robert Duncan and Duncan Aviation Todd has been Chairman of Duncan Aviation since 2007, and he’s seen the company ride the waves, the highs and lows, of the business aviation industry.

Todd has been Chairman of Duncan Aviation since 2007, and he’s seen the company ride the waves, the highs and lows, of the business aviation industry. Yesterday, at the annual AEA convention in Orlando, Florida, Robert was given a life-time achievement award, recognizing his contributions to the aviation industry and acknowledging everything he’s done at Duncan Aviation in the last 60 years.

Yesterday, at the annual AEA convention in Orlando, Florida, Robert was given a life-time achievement award, recognizing his contributions to the aviation industry and acknowledging everything he’s done at Duncan Aviation in the last 60 years. Robert’s father, Donald Duncan, founded Duncan Aviation in 1956 and this year, Duncan Aviation celebrates 60 years since that story began.

Robert’s father, Donald Duncan, founded Duncan Aviation in 1956 and this year, Duncan Aviation celebrates 60 years since that story began.

“I had been working for Learjet when my 47-year-old father had a heart attack, so I decided to accept the Duncan Aviation job offer and move back to Nebraska,” says Jeannine. “I gave my notice and said I was going to work for Duncan Aviation. People at Learjet took me aside and tried to talk me out of it. This was shortly after Donald had died, and they didn’t think the company would survive. They underestimated Robert and his entrepreneurial talent. He’s smart, open to new ideas, and willing to take risks. I’ve never regretted my decision to work for Robert.”

“I had been working for Learjet when my 47-year-old father had a heart attack, so I decided to accept the Duncan Aviation job offer and move back to Nebraska,” says Jeannine. “I gave my notice and said I was going to work for Duncan Aviation. People at Learjet took me aside and tried to talk me out of it. This was shortly after Donald had died, and they didn’t think the company would survive. They underestimated Robert and his entrepreneurial talent. He’s smart, open to new ideas, and willing to take risks. I’ve never regretted my decision to work for Robert.” Established in 1986, the Fort Lauderdale shop has always been located in space rented from and shared with other businesses. As those businesses grew and expanded, the Duncan Aviation shop would have to relocate. Earlier this year, Satellite Operations Manager Matt Nelson and Manager of the Fort Lauderdale shop Brian Redondo realized it would be beneficial for customers if the satellite stopped bouncing around and set up shop in its own hangar.

Established in 1986, the Fort Lauderdale shop has always been located in space rented from and shared with other businesses. As those businesses grew and expanded, the Duncan Aviation shop would have to relocate. Earlier this year, Satellite Operations Manager Matt Nelson and Manager of the Fort Lauderdale shop Brian Redondo realized it would be beneficial for customers if the satellite stopped bouncing around and set up shop in its own hangar.

In 1978, Phil Porter was hired as Duncan Aviation’s first logistics manager; although, at the time, he was called a parts runner. Nearing the completion of his fourth decade at Duncan Aviation, Phil took some time to reflect on his long tenure with the company.

In 1978, Phil Porter was hired as Duncan Aviation’s first logistics manager; although, at the time, he was called a parts runner. Nearing the completion of his fourth decade at Duncan Aviation, Phil took some time to reflect on his long tenure with the company. When Duncan Aviation won the exclusive rights as master distributor for Piper (including Aztecs and Cubs) parts, Duncan Aviation began regularly shipping parts worldwide.

When Duncan Aviation won the exclusive rights as master distributor for Piper (including Aztecs and Cubs) parts, Duncan Aviation began regularly shipping parts worldwide. In April 2015, the 61-year-old amphibious aircraft landed at Duncan Aviation’s Lincoln, Nebraska, facility to get fitted with its new interior—or, more accurately, an interior.

In April 2015, the 61-year-old amphibious aircraft landed at Duncan Aviation’s Lincoln, Nebraska, facility to get fitted with its new interior—or, more accurately, an interior.

He’d been working for a company that refurbished aircraft interiors in 1981 when his good friend Chip Mosley encouraged him to take a look at Duncan Aviation.

He’d been working for a company that refurbished aircraft interiors in 1981 when his good friend Chip Mosley encouraged him to take a look at Duncan Aviation. the upholstery specialists, Mike could do a little of everything, and I focused on completions and modifications,” says Matt.

the upholstery specialists, Mike could do a little of everything, and I focused on completions and modifications,” says Matt.